Automobile Damping and Silencing Sheet SS2014208

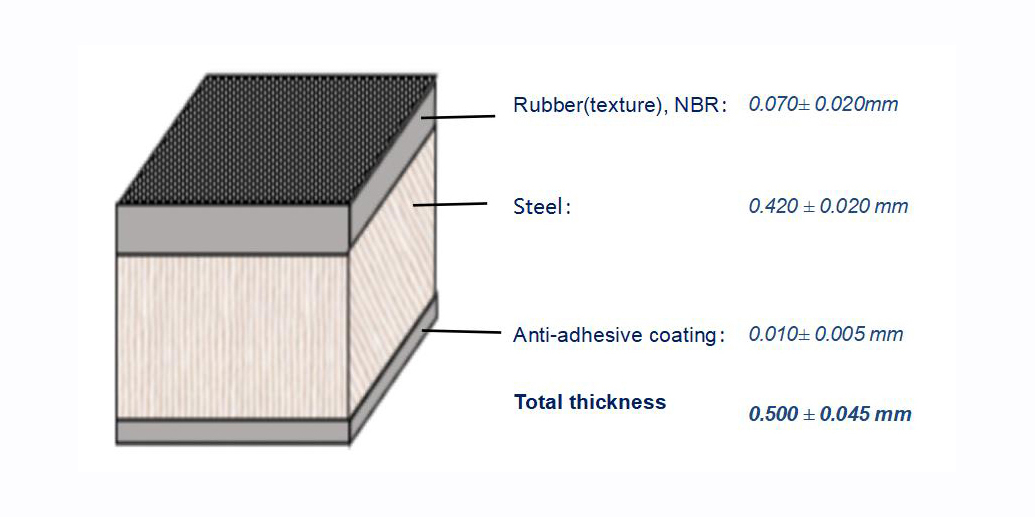

Products Specification

| Corrosion | ·Level 0-2 according to ISO2409 -measured according to VDA-309 ·The under-paint corrosion starting from stamped edges is less than 2 mm |

| NBR Temperature Resistance | ·The maximum instantaneous temperature resistance is 220℃ ·48 hours of conventional temperature resistance of 130 ℃ ·Minimum temperature resistance -40℃ |

| MEK Test | ·MEK = 100 surface without falling off cracking |

| Caution | · It can be stored at room temperature for 24 months, and a long storage time will lead to product adhesion. · Do not store in wet, rain, exposure, high temperature environment for a long time, so as not to cause product rust, aging, adhesion, etc. |

Products Description

The automobile damping and silencing pad is an accessory used to reduce or eliminate the noise during brak-ing. It is an important component of the automobile brake pad. It is arranged on the steel back of the brake pad. When the brake pad is braking,it plays a certain damping effect on the vibration and noise caused by the brakepad pad pad. The brake system is mainly composed of brake lining (friction material), steel back (metal part) and damping and silencing pads.

Silencing principle: brake noise is generated by friction vibration between friction plate and brake disc.The in-tensity of the sound wave will change once from the friction lining to the steel back, and once again from thesteel back to the silencing plate.The phase resistance of layers and the avoidance of resonance play a role inreducing the noise.

Products Feature

The rubber coating has strong adhesion and is suitable for high temperature environments and fluids such as engine oil, antifreeze and coolant. The thickness of the steel plate and rubber coating is uniform, and the surface is flat and smooth. The steel plate is treated with anti-rust treatment and has good corrosion resistance.

Mainly used for accessories and engine gaskets, excellent high and low temperature resistance. Good anti-aging properties. Good sealing performance for gases and fluids. Excellent compression, recovery and stress relaxation properties.

Rubber coated laminates are a damping (CLD) material based on a metal layer vulcanised with rubber to produce a robust and durable laminate. This provides excellent damping of structural noise and can be cut and moulded to suit most surfaces. Typical applications are in engine covers such as gearbox covers, valve covers, chain covers and oil sumps. Made from pressed vulcanised steel and rubber, they have a robust design and can be moulded and cut into parts using traditional pressing operations. We use these materials to produce customised products for customer requirements.

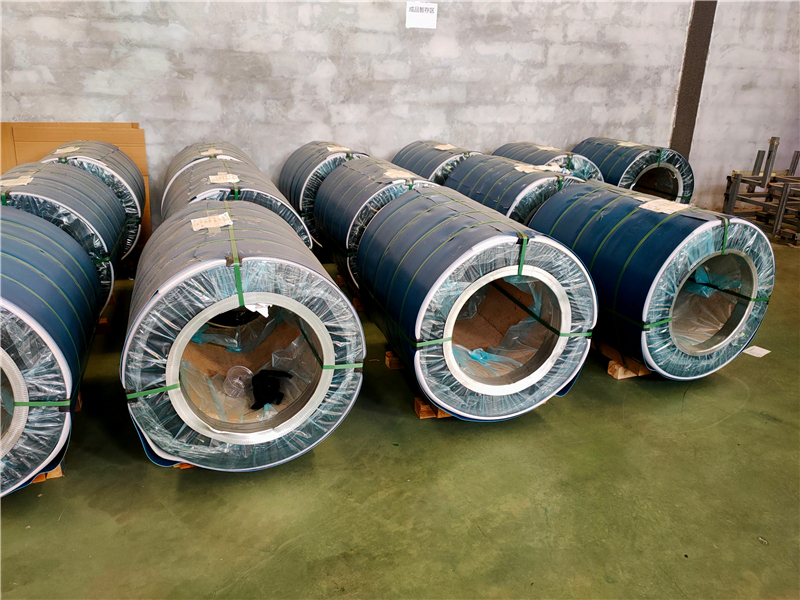

Factory Pictures

We have independent refining workshop, cleaning steel workshop, slitting car rubber, the total length of the main production line reaches more than 400 metres, so that every link in the production of their own hands, so that customers feel at ease.

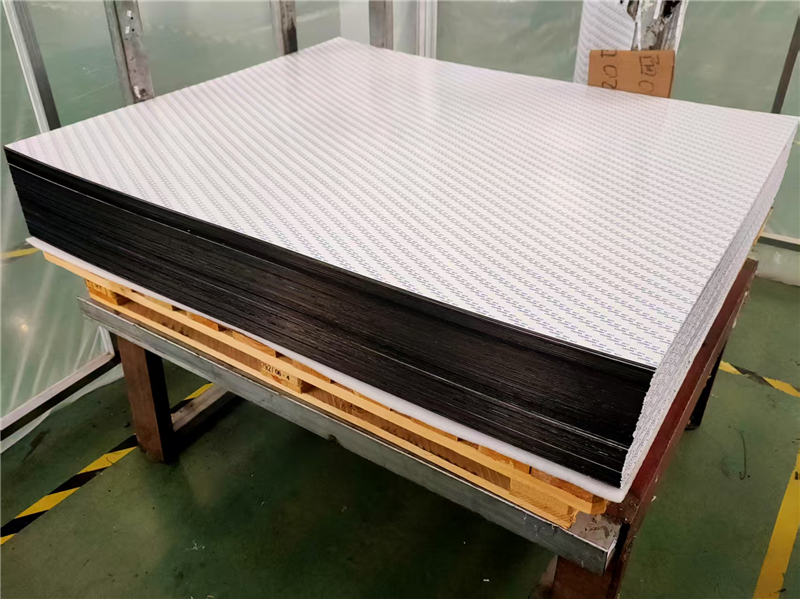

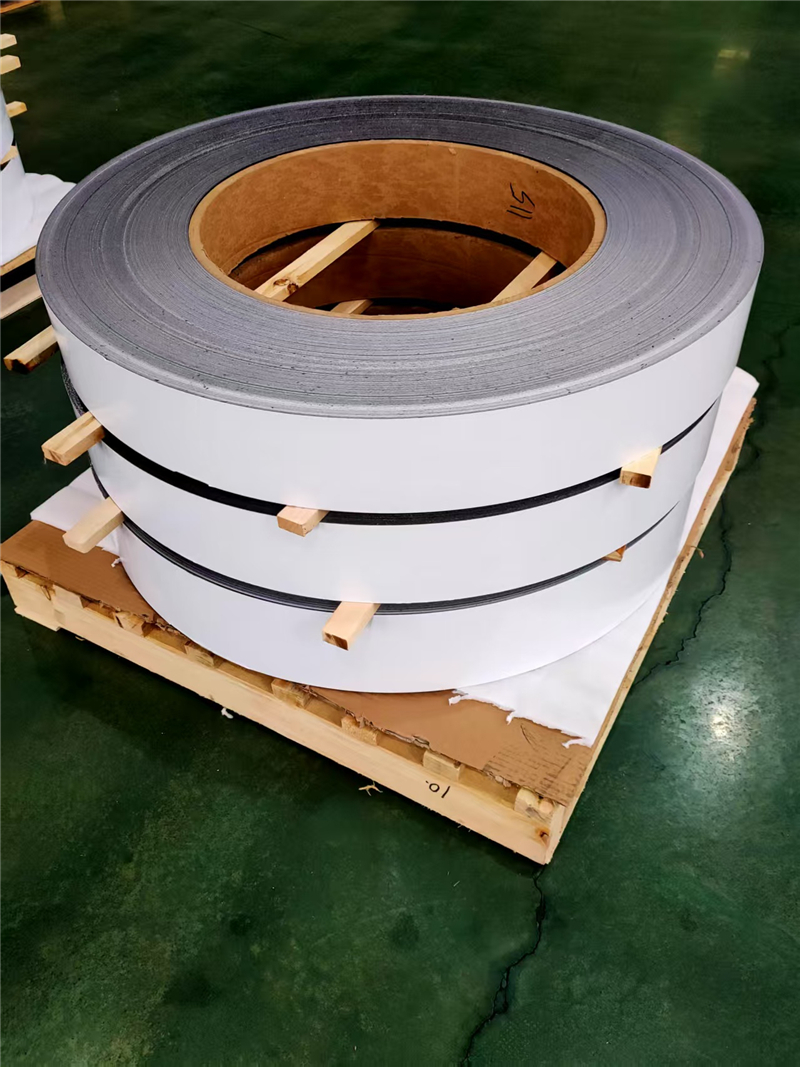

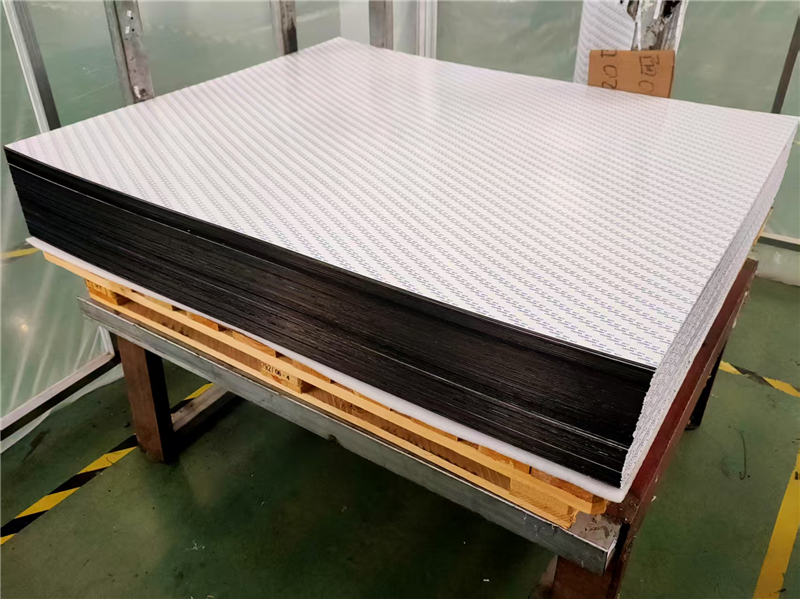

Products Pictures

Our material can be combined with many kinds of PSA (cold glue); we now have different thickness of cold glue. Can be customised according to customers

Different glues have different characteristics, while rolls, sheets and slit processing can be produced according to customer requirements. To meet the customer's requirements

Scientific Research Investment

Now it has 20 sets of professional testing equipment for silencing film materials andtesting means of link testing machine, with 2 experimenters and 1 tester. After the completion of the project, a special fund of RMB 4 million will be invested toupgrade the new equipment.

Professional Testing Equipment

Experimenters

Tester

Special Fund