Automobile Damping and Silencing Sheet DC40-03B43

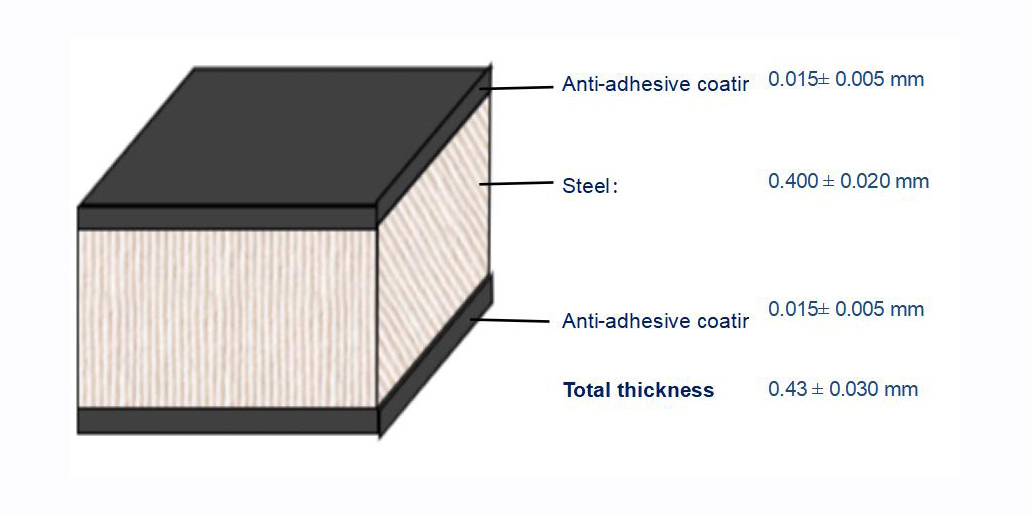

Products Specification

| Corrosion | · Level 0-2 according to ISO2409 -measured according to VDA-309 · The under-paint corrosion starting from stamped edges is less than 2 mm |

| Caution | · It can be stored at room temperature for 24 months, and a long storage time will lead to product adhesion. · Do not store in wet, rain, exposure, high temperature environment for a long time, so as not to cause product rust, aging, adhesion, etc. |

Products Description

The automotive shock-absorbing and sound-deadening pad is a critical accessory engineered to minimize or eliminate noise during vehicle braking. As an integral part of automobile brake pads, it is mounted onto the steel backing of the brake pad assembly. When the brake pads engage, the pad effectively absorbs vibrations and suppresses noise generated by friction between the brake pad and rotor. The automobile brake system primarily comprises three components: the friction lining (friction material), the steel backing (metal part), and the vibration-damping mat, which work collaboratively to ensure optimal braking performance and passenger comfort.

Silencing Principle

Brake noise originates from friction-induced vibrations between the friction lining and the brake disc. Sound waves undergo two critical impedance changes as they propagate: first, when transmitted from the friction lining to the steel backing, and second, when transmitted from the steel backing to the damping pad. The phase impedance mismatch between these layers, combined with resonance avoidance, effectively attenuates noise. This scientific principle ensures that our damping pads deliver superior noise reduction in real-world driving conditions.

Product Highlights

Metal Substrates: Available in thicknesses ranging from 0.2mm to 0.8mm and widths up to 1000mm, our substrates cater to diverse application needs.

Rubber Coatings: Offered in thicknesses from 0.02mm to 0.12mm, with single- and double-sided NBR (Nitrile Butadiene Rubber) coatings to meet specific customer requirements.

Cost-Effectiveness: Serves as a reliable alternative to imported materials, delivering robust vibration and noise damping at a competitive price point.

Surface Treatments: The material undergoes advanced anti-scratch treatment, ensuring long-lasting durability and resistance to surface damage. Surface colors can be customized (e.g., red, blue, silver) with non-transferable pigments for a premium finish. Upon request, we also produce cloth-coated panels with a smooth, texture-free surface.

Factory Pictures

Our factory is equipped with state-of-the-art infrastructure, including:

An independent refining workshop for material purity.

A dedicated steel cleaning workshop to ensure flawless substrate preparation.

Advanced slitting and rubber coating machinery for precision processing.

The total length of our main production line exceeds 400 meters, enabling us to oversee every stage of manufacturing with stringent quality control. This vertical integration guarantees that customers receive products of the highest caliber, with full traceability and reliability.

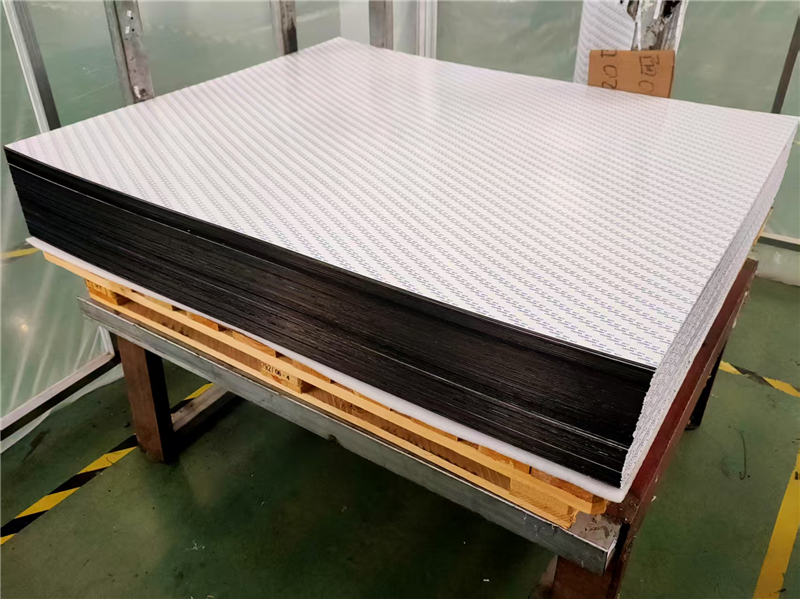

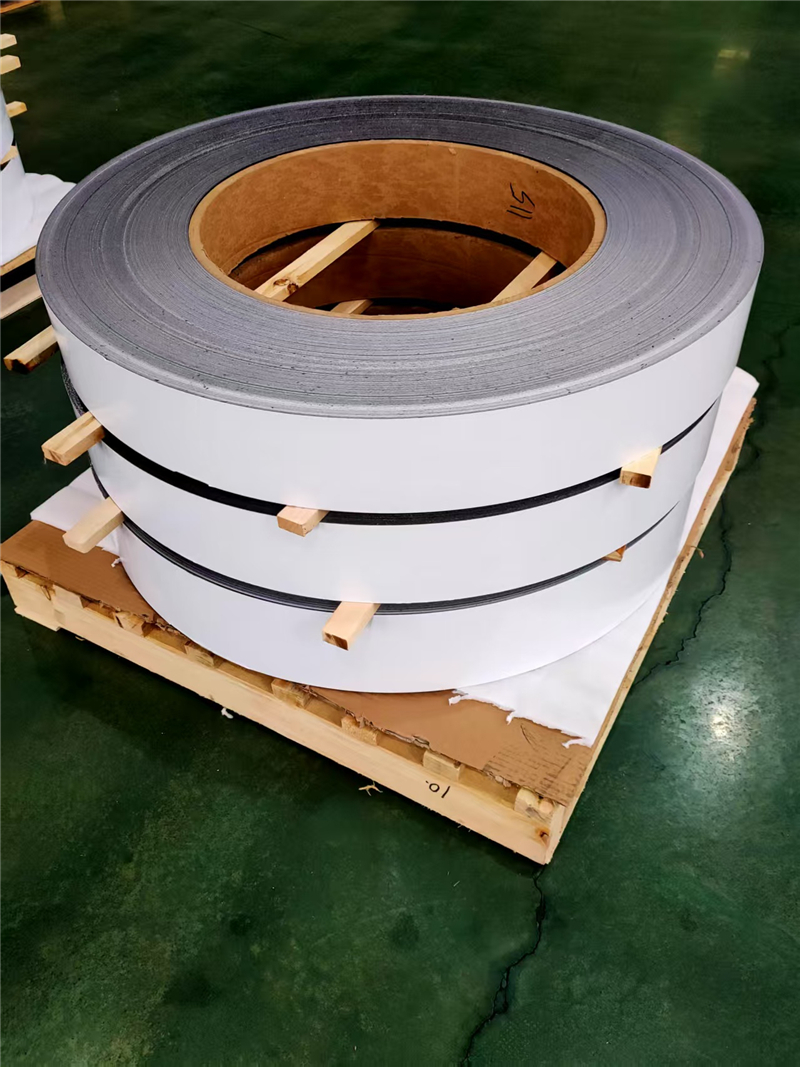

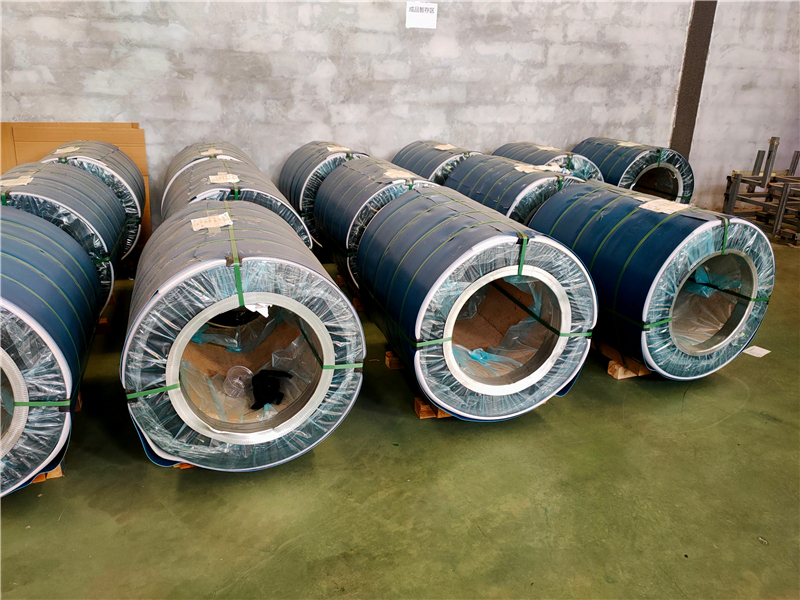

Products Pictures

Our material can be combined with many kinds of PSA (cold glue); we now have different thickness of cold glue. Can be customised according to customers

Different glues have different characteristics, while rolls, sheets and slit processing can be produced according to customer requirements. To meet the customer's requirements

Scientific Research Investment

Now it has 20 sets of professional testing equipment for silencing film materials andtesting means of link testing machine, with 2 experimenters and 1 tester. After the completion of the project, a special fund of RMB 4 million will be invested toupgrade the new equipment.

Professional Testing Equipment

Experimenters

Tester

Special Fund