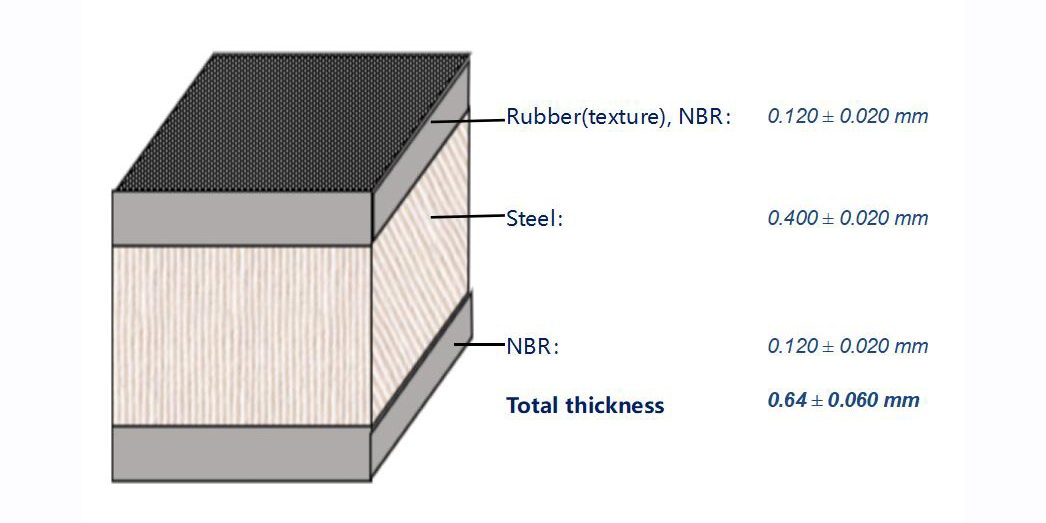

Automobile Damping and Silencing Sheet DC40-02C

Products Specification

| Corrosion | ·Level 0-2 according to ISO2409 -measured according to VDA-309 ·The under-paint corrosion starting from stamped edges is less than 2 mm |

| NBR Temperature Resistance | ·The maximum instantaneous temperature resistance is 220℃ ·48 hours of conventional temperature resistance of 130 ℃ ·Minimum temperature resistance -40℃ |

| Caution | · It can be stored at room temperature for 24 months, and a long storage time will lead to product adhesion. · Do not store in wet, rain, exposure, high temperature environment for a long time, so as not to cause product rust, aging, adhesion, etc. |

Products Description

Automotive vibration-damping noise suppression components serve as essential elements in braking systems to mitigate operational acoustics. Functioning as a critical brake assembly element, this noise-control layer is mounted on the brake pad's steel backing plate. During braking maneuvers, it effectively attenuates vibrational energy and acoustic emissions generated by friction interactions within the system. A complete brake unit typically comprises three primary sections: the friction contact surface (brake lining), structural support base (metal substrate), and integrated noise-reduction modules.

Noise attenuation mechanism: Brake-generated sound originates from oscillatory friction between the contact material and rotor surface. Acoustic wave propagation undergoes dual-phase modification - initially through transmission from the friction interface to the metallic substrate, then subsequently through the sound-absorbing layer. This multi-stage energy dissipation process achieves noise reduction through two primary physical phenomena: interlayer acoustic impedance mismatching that disrupts wave transmission continuity, and strategic resonance frequency separation through specific structural design parameters.

Products Feature

The metal substrate has a thickness ranging from 0.2mm to 0.8mm, with a maximum width of 1000mm. The rubber coating thickness falls between 0.02mm and 0.12mm. Both single-sided and double-sided NBR rubber-coated metal materials are available to meet diverse customer needs. These materials offer excellent shock absorption and noise reduction capabilities, and are cost-effective alternatives to imported materials.

The material surface undergoes anti-scratch treatment, ensuring high scratch resistance. Additionally, the surface color can be tailored to customer preferences, offering options such as red, blue, silver, and other non-transmissible hues. Upon request, we can also manufacture cloth-patterned coated sheets without any grain texture.

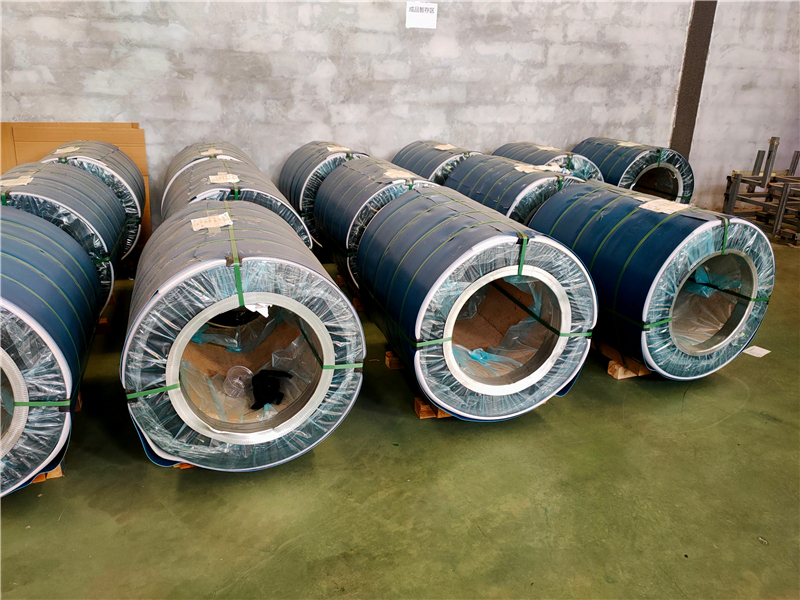

Factory Pictures

We have independent refining workshop, cleaning steel workshop, slitting car rubber, the total length of the main production line reaches more than 400 metres, so that every link in the production of their own hands, so that customers feel at ease.

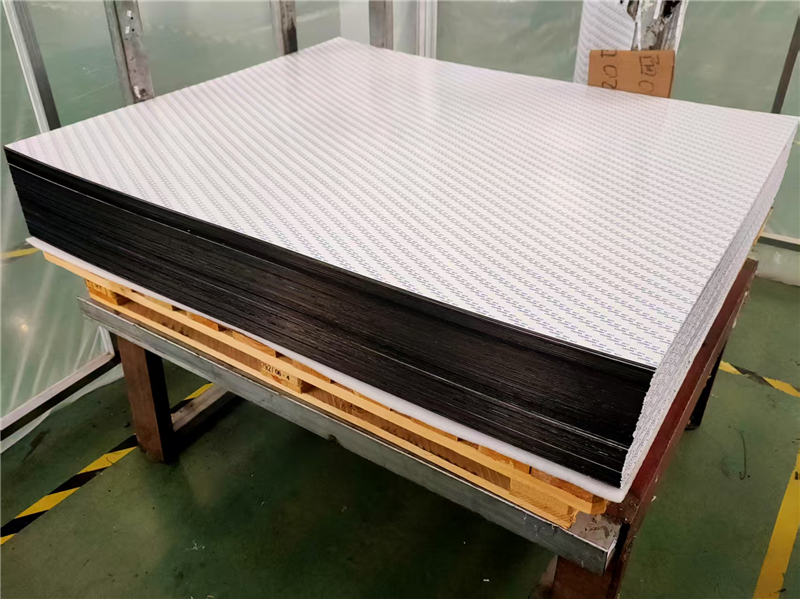

Products Pictures

Our material can be combined with many kinds of PSA (cold glue); we now have different thickness of cold glue. Can be customised according to customers

Different glues have different characteristics, while rolls, sheets and slit processing can be produced according to customer requirements. To meet the customer's requirements

Scientific Research Investment

Now it has 20 sets of professional testing equipment for silencing film materials andtesting means of link testing machine, with 2 experimenters and 1 tester. After the completion of the project, a special fund of RMB 4 million will be invested toupgrade the new equipment.

Professional Testing Equipment

Experimenters

Tester

Special Fund