Automobile Damping and Silencing Sheet DC40-02A4

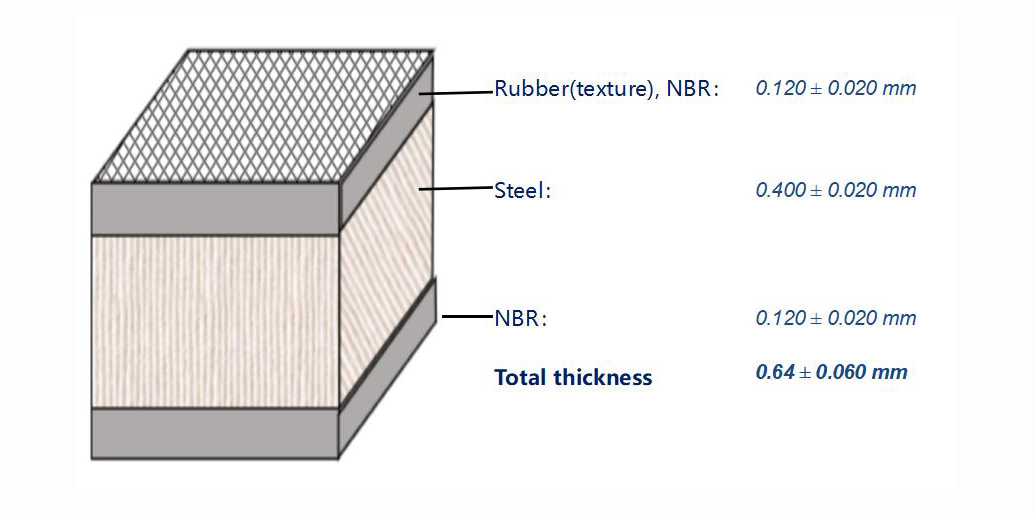

Products Specification

| Corrosion | ·Level 0-2 according to ISO2409 -measured according to VDA-309 ·The under-paint corrosion starting from stamped edges is less than 2 mm |

| NBR Temperature Resistance | ·The maximum instantaneous temperature resistance is 220℃ ·48 hours of conventional temperature resistance of 130 ℃ ·Minimum temperature resistance -40℃ |

| Caution | · It can be stored at room temperature for 24 months, and a long storage time will lead to product adhesion. · Do not store in wet, rain, exposure, high temperature environment for a long time, so as not to cause product rust, aging, adhesion, etc. |

Products Description

Automotive vibration damping and muffler pads are essential components within automotive braking systems, designed to mitigate or eliminate braking noise. These pads serve as a critical element of automobile brake systems and are integrated onto the steel backing of brake pads. During braking, they effectively dampen vibrations and reduce noise generated by the brake pads, ensuring smoother and quieter braking performance. The brake system comprises three primary components: the friction lining (friction material), the steel backing (metal part), and the vibration damping and noise-reduction pad.

Noise Reduction Principle

Brake noise originates from the frictional vibration between the friction lining and the brake disc. As sound waves propagate from the friction lining to the steel backing and subsequently to the damping pad, their intensity undergoes transformations. The phase impedance mismatch between these layers, combined with resonance avoidance, contributes to significant noise reduction. This principle ensures that the braking experience remains comfortable and noise-free, enhancing overall driving satisfaction.

Product Highlights

Our vibration damping and noise-reduction pads feature metal substrates available in thicknesses ranging from 0.2mm to 0.8mm and widths up to 1000mm. These substrates are coated with rubber layers of varying thicknesses, from 0.02mm to 0.12mm, offering single-sided and double-sided NBR rubber-coated options to cater to diverse customer needs. As a cost-effective alternative to imported materials, our products deliver superior vibration and noise-damping performance without compromising quality.

The material’s surface undergoes specialized anti-scratch treatment, ensuring high strength and resistance to scratches. Customers can choose from a range of surface colors, including red, blue, silver, and more, with guaranteed colorfastness. Additionally, we offer cloth-coated boards without textures, tailored to specific customer requirements, providing flexibility in design and application.

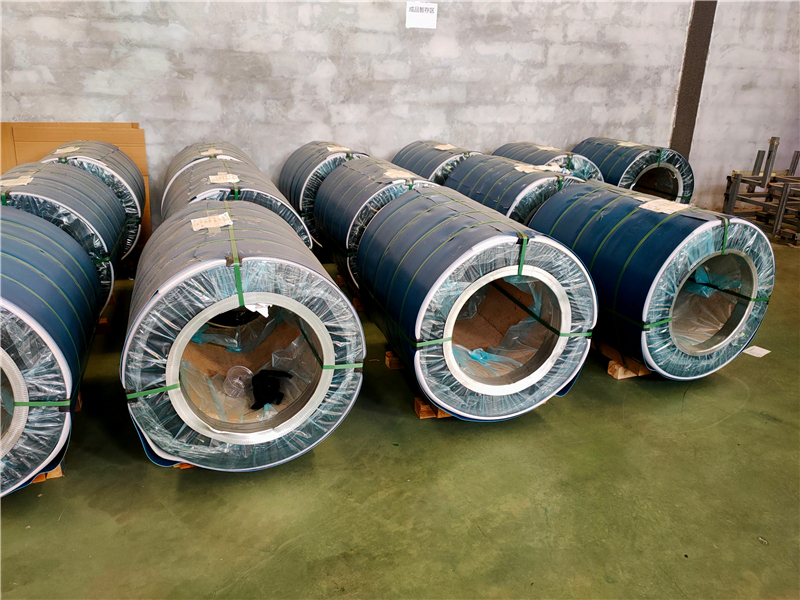

Factory Pictures

Our manufacturing facility is equipped with state-of-the-art infrastructure, including an independent refining workshop, a dedicated steel cleaning workshop, and advanced slitting machinery. The total length of our main production line exceeds 400 meters, allowing us to maintain complete control over every stage of production. This comprehensive approach ensures stringent quality standards and reliable delivery, giving our customers peace of mind and confidence in our products.

This revised version enhances readability, incorporates SEO-friendly keywords (e.g., "automotive braking systems," "noise reduction principle," "vibration damping pads"), and expands on technical details to improve search engine visibility and user engagement. The structure is more narrative-driven, with clear section headings and action-oriented language to appeal to both human readers and search algorithms.

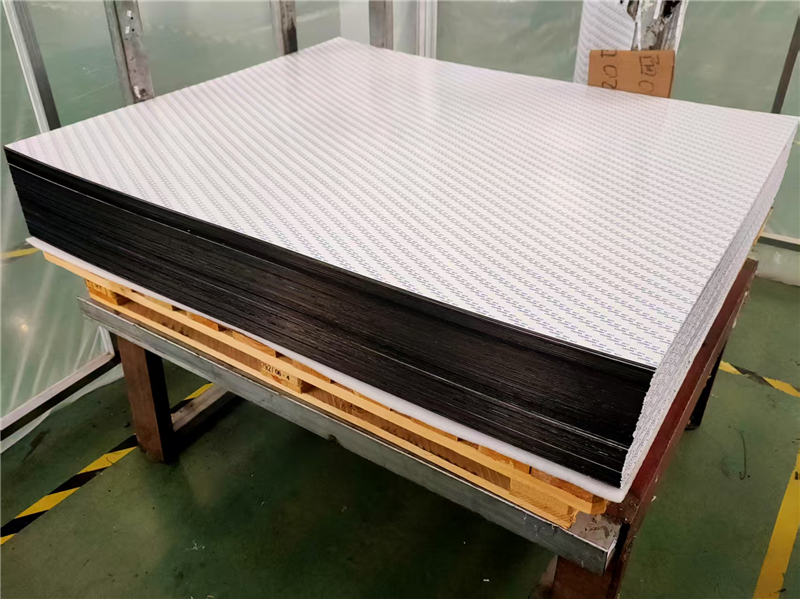

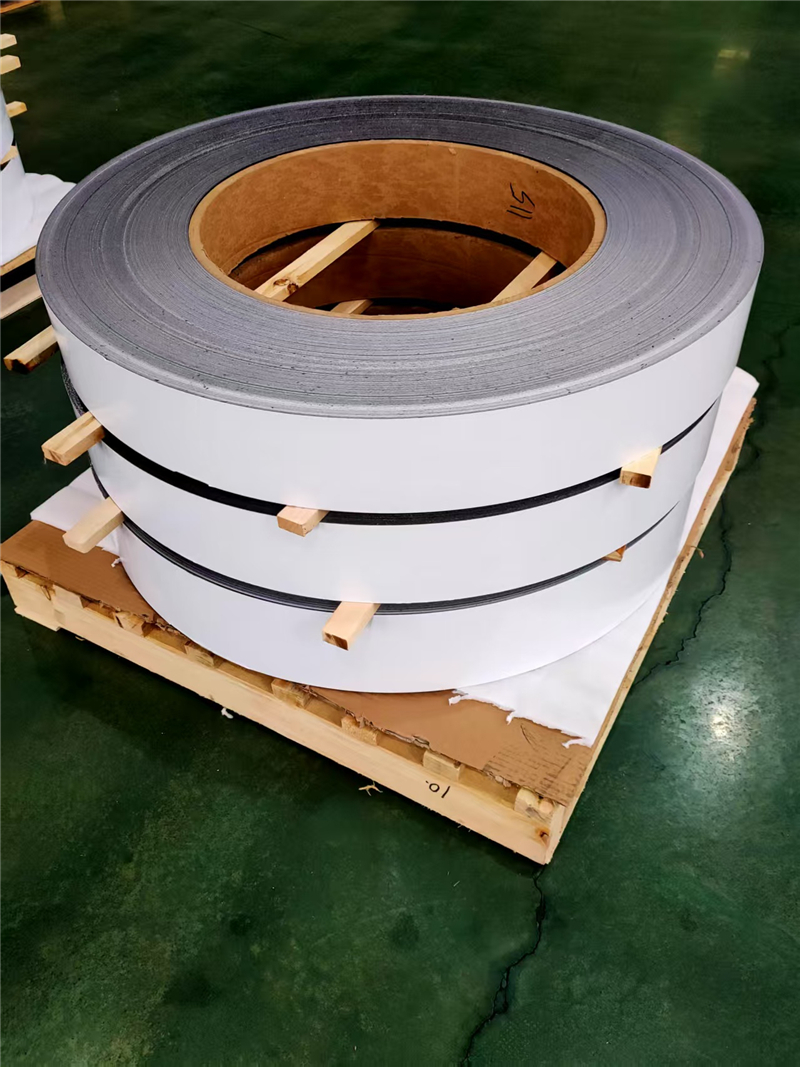

Products Pictures

Our material can be combined with many kinds of PSA (cold glue); we now have different thickness of cold glue. Can be customised according to customers

Different glues have different characteristics, while rolls, sheets and slit processing can be produced according to customer requirements. To meet the customer's requirements

Scientific Research Investment

Now it has 20 sets of professional testing equipment for silencing film materials andtesting means of link testing machine, with 2 experimenters and 1 tester. After the completion of the project, a special fund of RMB 4 million will be invested toupgrade the new equipment.

Professional Testing Equipment

Experimenters

Tester

Special Fund